Ingredient Functionality

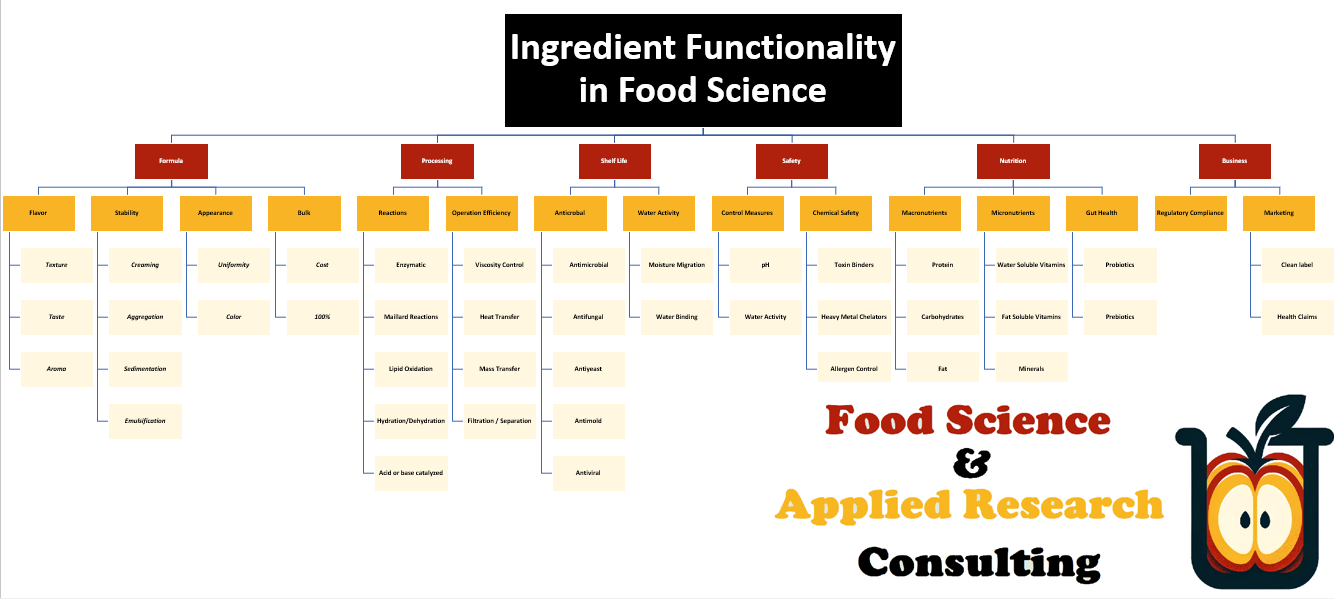

Figure 1. Categorization of ingredient functionality in food based on important use cases

Introduction

What do we mean when we say we use an ingredient for its functionality? What do academic papers mean when they say things like techno-functional, chemosensory, or organoleptic properties? Personally, I think these academics are really just trying to sound smart, and they don’t actually know what these words mean for real food. However, ingredient functionality can and does mean something; more importantly, this world is critical for concisely communicating why anyone would choose to pay to use one of these ingredients in their product or process. Unfortunately, there are too many imprecise definitions of ingredient functionality. This is because academics don’t usually understand the practical details of product development and commercial production, and industry folks are too busy trying to launch products ever faster.

Thus, the object of this article is to help provide a framework for classifying, communicating, selecting/optimizing, and measuring ingredient functionality. The benefits of this system are better communication, faster and cheaper development time, and higher quality products. This is useful for ingredient manufacturers who struggle to explain why someone should use a specific ingredient or set of ingredients. It allows the product developer to select the right ingredients and avoid marketing hype consistently. Lastly, this will help academics more effectively communicate both with each other and, more importantly, with the industry when trying to quantitative and qualitatively understand or improve specific ingredients. If you have ever built an industrial process for producing a specific ingredient or a class of ingredients (Patents and IP; How to Save 300M a Year), then you are probably aware of how hard it can be to find academic literature that actually helps*.

The Definition

For those who don’t know, food is typically made up of one or more ingredients (at least the ones that food scientists would usually work on); these ingredients can be selected for several qualitative and quantitative attributes. This specific use case provides some measurable value that I call functionality. This is tricky to understand in practice because ingredients can have multiple functions in the same product. This value changes based on a number of factors, including concentration, the presence of other ingredients, processing, and the order of addition. Thus, functionality can be very context specific and difficult to measure objectively.

* By help, I mean providing scalable solutions that don’t require experimentation. Often, I have found that I have to perform several experiments to arrive at a complete understanding of the phenomena. In some cases, I have to conduct a literature review and a whole experiment. This kind of work would easily be an academic manuscript were I not doing it for clients / previous employers. In an industrial context, useful means we can make money or save money by leveraging a manuscript's knowledge.

An Overview of the Framework

As you can see, I have categorized functionality based on the most industrially relevant use cases. I will be referring to this as level 1. These categories are still very broad and typically get more value from going at least one level deeper. In level 2, I have segmented the categories to be more context specific. However, to truly understand the value of a specific ingredient, we must go to level 3. In level 3, we start thinking about how we describe and measure this attribute. I haven’t compiled a complete list of specific measurements, but level 4 is the way we can evaluate this ingredient. Measurement can be conducted in the complete system, a model system, or by itself, depending on the attribute and difficulty of measuring in the full system.

Level 1 (Red): The most general reason for selecting an ingredient

Level 2 (Orange): Subcategories providing more detail.

Level 3 (Tan-yellow): Sub-subcategories that can be quantified or qualified.

Level 4 (Blue): The lowest level is a specific ingredient evaluation technique.

Here is an example of the framework using xanthan gum, a common food additive.

Level 1: Formula

Level 2: Flavor

Level 3: Texture

Level 4: Increasing Viscosity

Using our system, a product developer can quickly identify xanthan gum's primary function and compare it with other thickeners based on specific viscosity requirements. The viscosity can be measured using a viscometer or rheometer. It also makes evaluating tradeoffs much easier, as we can evaluate all the relevant secondary functionalities we may get or lose when changing ingredients / usage levels.

Currently, this framework contains 6 level 1 categories. The first are the ingredients that add functionality directly to a Formula. This category is most relevant for a product developer, and most, if not all, of these ingredients will appear on the ingredient statement. Next on the list is Processing. Most of the time, these ingredients will not appear on the ingredient statement. Ingredients added or generated in this category are patented and proprietary processes that allow businesses to achieve excellence (Patents and IP). When a company develops a patented or proprietary process, it has something that its competition can’t reverse-engineer.

Furthermore, these companies can develop a superior cost structure or quality that sets their products apart and gives their brand serious differentiation. Any consumer packaged goods company can tell you why Shelf Life is important. This category is all about ensuring the food quality (see level 2 of Formula) is maintained. No one will buy moldy products; consumers expect food to taste the same on day one or week 3. These ingredients will often be named on the ingredient list, although a growing class of natural preservatives avoids some clean label issues. The first version of my framework (Smart Formulation) combined Shelf Life with safety; however, safety is too important not to have its category.

Furthermore, much like processing, many ingredients are added during the processing step purely to enhance the safety of the food. In these cases, the ingredients may be deemed part of the processing step and won’t appear on the ingredient label. While some product developers might be tempted to place Nutrition within the formula category, this space is too complex and unique to be a level 2 category. Although this category includes foods marketed as healthy, this space also includes medical and highly regulated categories where the full diet of the consumer is considered. Lastly, we have the Business category here, and we include all the various reasons for adding an ingredient that doesn’t fit into the other categories.

Ingredient Functionality Formula

Formula

The functionality contained within a formula (level 2) includes Flavor, Stability, Appearance, and Bulk.

Flavor

Flavor is almost too important and too complex to summarize, but when we say we like the flavor of food, we could be referring to one or more attributes. In level three, we have the Texture, Taste, and Aroma. Texture is the physical attribute of food. This is one of my specialties, but I’ll keep the description brief. Texture includes many attributes of moving food in your mouth and how it might feel to pick it up or compress it with your hands. The Texture attributes are how thick or creamy a beverage is or how stretchy melted mozzarella cheese is.

Taste is well-defined and refers to the 5 tastes: salty, sweet, sour, bitter, and umami (savory). Although this category is easy to measure and explain mechanistically, much of the uniqueness of foods comes from our last category. In many cases, these compounds will be added in 1-5% as they can be readily seen on ingredient statements.

Aroma includes all the volatile compounds, and they are responsible for many unique and hard-to-replicate flavors found in food. They are used at very low levels and are highly matrix-specific. Measuring or even determining which of the thousands of compounds are most important for getting the aroma right can be very difficult. In most cases, these will appear simply as natural or artificial flavors.

Stability

Ingredients added for Stability may help preserve Texture or Flavor and, in general, maintain the quality of the food. In most cases, these ingredients help prevent products from developing defects that consumers would reject. Level 3 includes Creaming, Aggregation, Sedimentation, and Emulsification. Creaming and Sedimentation are two kinds of separation that can occur in many liquids and even some solids (syneresis in yogurt; that pool of water). The main difference between them is the direction of their movement. Creaming involves material moving to the top, while sedimentation involves particles settling on the bottom. You can see an example of both of these in milk. Creaming can occur in non-homogenized milk, while sedimentation will occur in shelf-stable milk as it ages.

Emulsifiers are ingredients that possess both hydrophobic and hydrophilic groups and thus help to create a stable mixture. This includes oil and water (salad dressing), water, air (foam on a cappuccino), and more complex mixtures such as ice cream (water, ice, air fat). An emulsifier is often added to prevent Creaming, Aggregation, or Sedimentation, as these are usually defects. However, some ingredients, such as xanthan gum, prevent creaming or sedimentation by making the solution more viscous, thus making it hard for particles to move and separate.

Appearance

The Appearance of a food can be broken down into the Color it possesses and how that Color is arranged (Uniformity). Many ingredients are explicitly added to enhance or provide a desirable color. Sometimes, you may desire a product that is one solid color, such as a chocolate bar. If the bar possesses blotches (called blooming, a type of separation), it would be less uniform and would be unappealing to consumers. On the other hand, many products must possess many different colors that should not mix or overlap too much. Neapolitan ice cream would be one example, and another might be the marbling (streaks of fat) on a steak. In the first case, you simply need to avoid having the different colors blend while making a plant-based stake specifically requires texturing and layering of ingredients to obtain a nonuniform appearance.

Bulk

While not exactly a functional ingredient in the traditional sense, this category is often overlooked when developing a product. This leads to scaleup issues and cost overruns. The level 3 categories here, Cost and 100% keep the price down and balance the formula. In most cases, ingredients added for cost also provide another functional property. The profit margins for many foods are quite low, and understanding which ingredients will allow you to keep your prices down is critical for operating a successful CPG business. These ingredients may enhance Taste or Aroma, improve Texture, or decrease processing costs. Regardless of their primary functionality, the secondary purpose is to avoid excessive amounts of highly expensive ingredients. Anyone who has spent time creating formulas in the food industry will tell you ratios are very important. When scaling a recipe, it is very important to have an ingredient that can be added or subtracted without changing the ratio of other ingredients. The most common ingredients that help serve this function are water, starch, or fiber (low-weight maltodextrin). These can also help keep the costs lower without changing the quality of the product.

Ingredient Functionality Processing

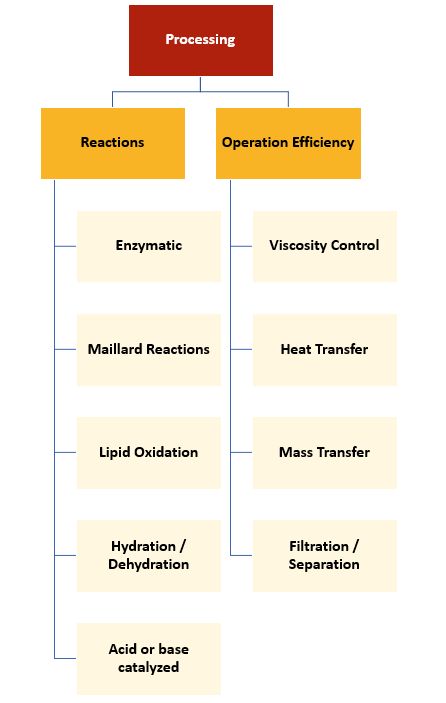

Processing

Currently, the Processing category only has two subcategories (level 2): Reactions and Operational Efficacy. For simplicity's sake, we will focus on adding ingredients to make whole CPG foods rather than creating individual ingredients. Thus, the Reactions category is focused on creating one or more compounds that impact attributes within the Formula category. This area can impact many other level 1 categories, including Shelf Life or Nutrition. However, I am focusing on this category because of its proprietary nature.

Reactions

In most cases, it wouldn’t be possible to see a difference based on the ingredient statement, yet these reactions can be critical for generating many useful attributes. Thus, Enzymatic, Maillard, Lipid Oxidation, Hydration / Dehydration, and Acid or Base-Catalyzed are distinguished by the necessary processing conditions rather than their exact output. This group may require specialized equipment or precise applications of temperature and pH. Enzymatic reactions could speed up natural processes or improve nutrition (lactose reduction in milk). Maillard reactions are leveraged for their unique flavors and sometimes for the color changes that occur. Lipid Oxidation reactions could be to create novel fat properties or prevent off flavors. Hydration and Dehydration ingredients, as well as Acidic or Basic ingredients, can impact the cost of many products or may be needed to aid the above reactions.

Operational Efficiency

In level 2, Operational Efficiency is focused on increasing the yield, lowering the cost, or improving the quality of the final product. This category adds ingredients for Viscosity Control, Heat Transfer, Mass Transfer, or Filtration and Separation. These ingredients can sometimes be removed before being sold as a finished product. Many industrial processes require specific and controllable pumping, keeping the viscosity in an optimal range. Sometimes, this translates to adding ingredients that temporarily disrupt high viscosities (adding sodium to specific gums to prevent proper hydration). In other cases, the viscosity is increased to reduce foaming or prevent separation. Ions are sometimes added to food to improve their ability to absorb heat (Heat Transfer). For example, increasing the salt content of food makes microwaving heat faster; thus, many foods served hot on airlines are much saltier than they otherwise would be. Ingredients to aid in Mass Transfer serve as carriers or prevent losses during industrial processing. Lastly, some Filtration and Separation processes are enhanced by changing the pH or adding ions that bind / interact with a target molecule.

Ingredient Functionality Shelf Life

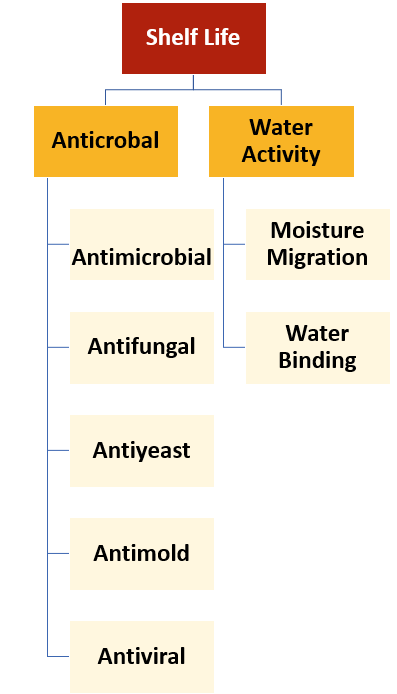

Shelf Life

For Shelf Life, the level 2 categories are Anticrobal and Water Activity.

Anticrobal

Anticrobal is a word I made up to include the various compounds that can be used to target specific microorganisms or sometimes viruses (when probiotics and fermentation are involved). These compounds may or may not be included in the ingredient statement (depending on usage level).

Water Activity

Maintaining the Water Activity is important for more than just keeping food safe. It is also needed to slow chemical reactions or maintain Texture (chips get stale partly because they absorb excess moisture from the air). Thus, the level 3 values to control Water Activity include compounds that prevent moisture migration by acting as physical barriers, including certain fats or waxes. The other mechanism for controlling water activity is to add ingredients that directly bind water; this includes proteins, starches, fibers, and ions.

Ingredient Functionality Safety

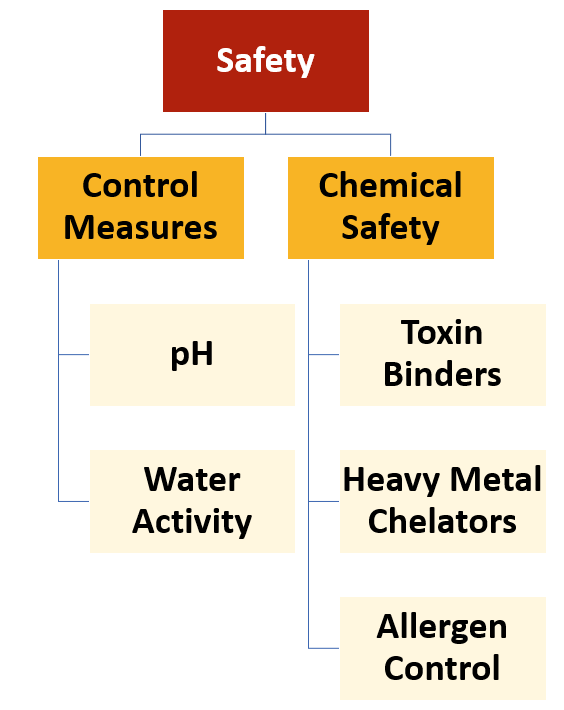

Safety

Ingredients used to maintain food safety can be classified into Control Measures and Chemical Safety. Level 3 Control Measures adjust the pH or water activity to kill spoilage and pathogenic organisms. This is typically done in conjunction with traditional thermal or non-thermal processing methods. While less commonly discussed, certain ingredients may be added to remove or control undesirable compounds found in food. The level 3 categories for Chemical Safety are Toxin Binders, Heavy Metal Chelators, and Allergen Control. In all cases, the goal is to remove, reduce, or otherwise identify undesirable compounds.

Ingredient Functionality Nutrition

Nutrition

The level 2 categories for Nutrition are Macronutrients, Micronutrients, and Gut Health. Ingredients in this category are selected specifically and explicitly to improve the nutrition label or fulfill a specific demographic niche.

Macronutrient

Those familiar with human nutrition will also be familiar with the first two categories and their level 3 categories. Macronutrient level three ingredients include Protein, Carbohydrates, and Fats.

Micronutrients

We require Micronutrients to stay healthy at lower doses; the level 3 categories include Water Soluble Vitamins, Fat Soluble Vitamins, and Minerals.

Gut Health

More and more research has highlighted the importance of our gut microbiota in maintaining our health. Thus, more products provide Prebiotics (the fibers and other compounds that support the growth of specific micrograms) or Probiotics (the organisms themselves). It is now more common for fermented foods to specifically highlight or try to maintain their probiotic activity. To do so, they typically need to add probiotics to help maintain the microorganisms before and during ingestion.

Ingredient Functionality Business

Business

There are only 2 level 2 categories at the time of writing: Regulatory Compliance and Marketing. I won’t be delving into the lower levels of Regulatory Compliance yet, as they are extremely specific for foods / processing. Marketing contains 2 level 3 categories: Clean Label and Health Claims. If an ingredient is in this category, the most important function is to help sell products / align with the brand. It does not have to have any measurable function in the other level 1 categories. It could even have negative functionality (I’m looking at you, pea protein isolate; Rethinking Plant-Based). However, it is added because the company and, presumably, the consumers are making purchasing decisions based on this ingredient. It is important to say that many ingredients have functionality in one or more of the other level 1 categories. Clean Label ingredients are used to keep the ingredient statement numerically small and avoid words that the target consumers find undesirable. There is no common or consistent definition of Clean Label, and it changes over time and between cultures. Ingredients added for Health Claims typically increase one or more Macronutrients, Micronutrients, or Gut Health. However, the ingredients in question may only improve nutrition on paper or are otherwise problematic for Aroma, Taste, or Texture.

Next Steps

Undoubtedly, there will be further changes to the level 1-3 structures as I have more time to reflect on my experience. I intend to add more level 3 categories to Business Regulation as some practical information is clearly missing. I’m also open to changing how Processing is categorized, as it may be too focused on chemistry rather than applications.

While most food science professionals approach this problem from a bottom-up approach, I have chosen to apply theory first (top-down). Thus, I have delayed categorizing the many ingredients that are commonly used in the food industry. When my time permits, I intend to start compiling a database of ingredients (generic at first). I will also add more level 4 examples as they become relevant to my current consulting work. Level 4 categories are the methods / contextually specific functionality; thus, the number is larger than the list of possible ingredients.

If you would like to contribute to this work or believe that this knowledge can help you with your existing projects, please email me (foodscienceappliedresearch@gmail.com) or click the Book Now icon on this website to schedule a meeting.